Entek

PM1000

Entek

PM1000  Pdf document of PM1000 Pdf document of PM1000

Pump Multiplexer

ENTEK PM1000 series pump multiplexer panel controls, protects

and automates 1 to 6 pumps for industrial applications, commercial

buildings and irrigation systems.

Accurate pressure

control with an analog pressure sensor eliminating problems

with mechanical switches

Electronic

safety control against dry running

Controls

up to 6 direct online connected pumps up to 10HP per pump

Sequence

control and lead pump switching

Automatic

switchover to replace a malfunctioning pump

Protection

for short circuit, over-current, phase-loss

Operator-friendly

programming interface

Delay feature

prevents frequent start-stops

LED indicators

for Alarm and In Operation signal for each pump

LED indicators

for High and Low Pressure

Manual override

of automatic functions

All measurement

and control functions are processed by a microprocessor

Typical Applications

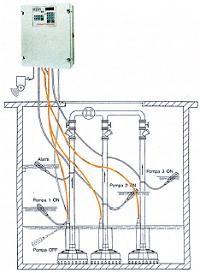

Submersible Waste Water Pump Control

Using level switches, PM1000 can be used to automate up to

6 submersible wastewater pumps. Input signals from up to 4

level switches at 4 different levels provide enhanced control.

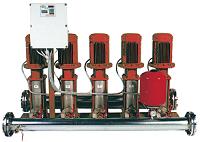

Line Pressure Control Applications

Using analog pressure

sensors, PM1000 can be used in industrial facilities or commercial

buildings in order to maintain a constant line pressure by

multiplexing required number of pumps. The line pressure can

be accurately maintained with the help of the microprocessor

control and analog pressure measurement in systems that have

air tank pressure balancing. Desired line pressure can be

set using the keypad interface.

Irrigation

Applications Irrigation

Applications

PM1000 is used in irrigation applications where demand fluctuations

are met by controlling multiple pumps. Using the microprocessor,

the pumps can be programmed to work in rotation and with sequential

control. Operation time is divided between the pumps with

lead pump switching to optimize wear and to extend the operating

life. The number of motors can be set to a desired value less

then the actual quantity, leaving a desired pump out of the

rotation sequence.

Technical Specifications

| Dimensions |

18"x15"x5" |

| Weight |

16 lbs |

| Digital Inputs |

4 dry contact inputs

for pressure or level switches |

| Analog Input |

1 pressure input,

4-20mA or 0-10V signal level |

| Operating Voltage |

230 V, 460V, 480V

3 phase |

| General Protection

Class |

NEMA12 - IP 54 |

| Cable Entry |

AC Power, Signal

Input, Pump Output (up to six) |

| Operating Temperature |

-40 °F to 185

°F |

|

|

|